With global temperatures likely to rise beyond the 1.5°C target set by climate experts, negative emissions technologies — most notably direct air capture (DAC) — become increasingly important for addressing CO2 already in the atmosphere. A new DAC approach is being pursued by Holocene Climate Corp. (Knoxville, Tenn.; www.theholocene.co). Holocene’s system is unique in its ability to operate at low temperatures, while still employing an aqueous-based approach amenable to traditional chemical-engineering scaling benefits.

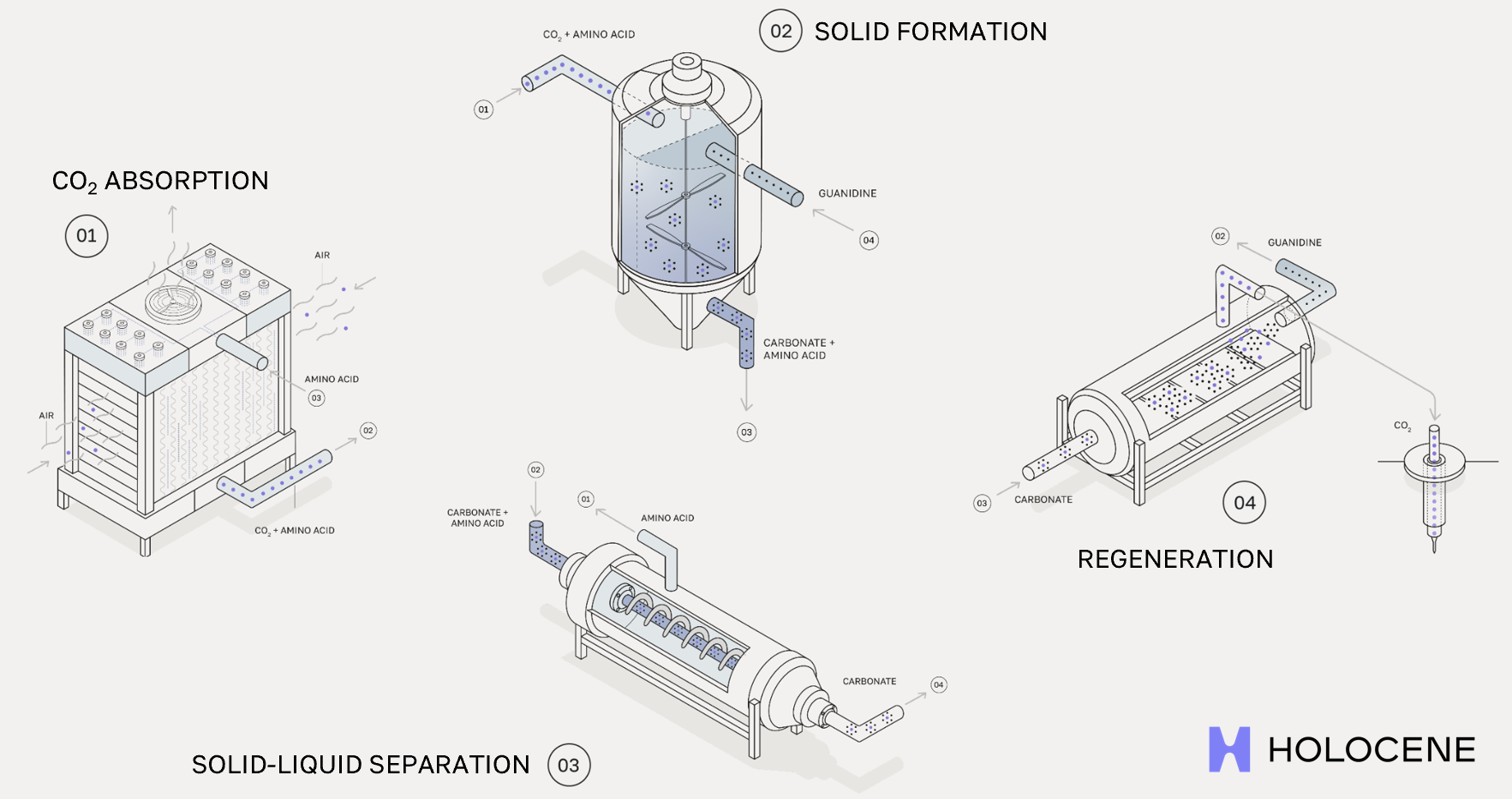

Leveraging technology licensed from Oak Ridge National Laboratory (ORNL; Oak Ridge, Tenn.; www.ornl.gov), Holocene developed a process with two distinct chemical loops (diagram): in the first, an amino acid solution is used to absorb CO2 from the air with an apparatus that is similar to the air-liquid contactor in a cooling tower. In a second step, guanidine compounds are added to the CO2-rich solution, forming an insoluble carbonate salt. The much lower solubility of the guanidine carbonate salt, compared to its guanidine precursor, drives the process and results in a solid, CO2-containing precipitate. The solid material is filtered and heated (110°C) to release the CO2, which is then sent on for further use or sequestration.

“Having two distinct loops increases the robustness of our process and lowers the energy requirements,” explains Holocene co-founder Keeton Ross. “We can keep the amino acids away from heat, where they would degrade. Also, we are able to heat only the solid to regenerate CO2, rather than wasting energy heating a large volume of water.”

The amino-acid markets are mature, and Holocene is focused on scaling up production and optimizing the performance of their guanidine derivatives.

Holocene has working bench-scale versions of all DAC unit operations, and is currently building its first integrated facility — with capacity of around 10 ton/yr CO2 — for planned commissioning at the end of 2023. This will be followed by the design of larger, commercially available facilities.